KINGS

PRODUCTS

No data

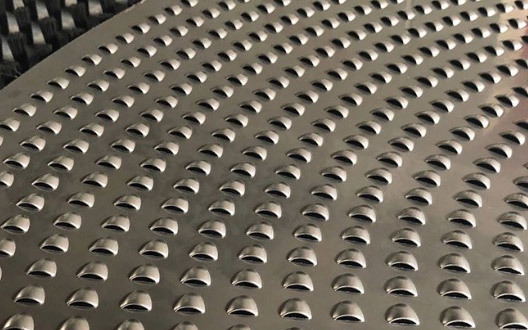

Cone mill screen-conidur hole screen

The conidur hole screen is a core component designed for efficient cutting. It adopts a conical structure and filing tooth shaped hole pattern to achieve fine granulation of hard or large particle materials through extrusion and shearing. Its stainless steel material (such as 304/316L) has both wear resistance and corrosion resistance, which can meet the demanding production environment requirements of sterile raw materials such as pharmaceuticals.

Compared to flat screens, conidur hole screen can reduce particle breakage, increase screening efficiency by more than three times, and effectively prevent screen hole blockage. Support customization of multiple aperture sizes as needed. This sieve is compatible with mainstream models such as Frewitt and Quadro, and is widely used in dry and wet granulation processes in the pharmaceutical, chemical, and food industries. Welcome to consult.

MORE

The cone mill screen is the core filtering component in the granulator, designed with a conical structure to achieve material classification and screening through vibration or rotation. Its stainless steel material has wear-resistant and corrosion-resistant properties, and the sieve aperture can be customized to meet different particle size requirements. This screen uses centrifugal force to separate qualified particles and residues, and with a step-by-step screening mechanism, it can efficiently process materials such as powders and particles. Mainly used in the pharmaceutical (such as sterile raw material granules), chemical, and food industries.The specifications of the screen of the square hole granulator include 3 * 3mm, 4 * 4mm, 5 * 5mm, and so on,Welcome to inquire.

MORE

This conical screen is suitable for the Frewitt CW-200 granulator, and Designed with a conical structure and made of stainless steel material, it has corrosion resistance, wear resistance, and anti clogging properties. Its working principle is to form multi-stage screening of materials on the surface of a conical sieve through mechanical vibration or rotation: larger particles are blocked by the sieve and undergo secondary crushing, while smaller particles enter the subsequent process through the sieve holes, achieving particle size classification and fine sizing. The aperture of the conical sieve can be customized according to production needs, supporting various designs such as filing holes and flat holes. It is suitable for dry/wet material granulation in industries such as pharmaceuticals, food, and chemicals, especially in scenarios such as sterile raw material crushing and solid formulation granulation. Our conical screen can be adapted to equipment from companies such as Frewitt, Quadro Comil, Glatt, Bohle, and so on, If you need,welcome to inquiry.

MORE

The conveyor mesh plates plate of the fiber dryer is made of high-temperature resistant stainless steel material (such as 304/316L), which is corrosion-resistant, anti-oxidation, and suitable for high temperature and high humidity environments of 150-300 ℃. A uniform hole array is set on the surface of the chain plate, combined with segmented temperature control and hole bundle hot air penetration technology, to accelerate the drying of fiber materials and maintain their shape integrity. Drying of textile fibers, non-woven fabrics, and bio based materials (bamboo/hemp fibers); Continuous production is applied in fields such as food processing (fruits and vegetables, grains) and chemical industry (resins, dyes). Our company can customize different specifications of chain plates according to customer needs. Our conveyormesh plates quality is excellent and can be adapted Qinhuangdao Tobacco Machinery、Yunnan CSSC、CPM Wolverine Proctor、Comas 、Mactavish、Garbuio Dicknson、ZFJ Textile、Bühler、CPM Wolverine Proctor、ANDRITZ、Famsun and so on.Welcome to inquire.

MORE

The fluidized bed dry plate for drying milk powder is a high-performance component designed specifically for the milk powder drying process. It adopts advanced porous design to ensure that the hot air flow can uniformly and stably penetrate the layer of milk powder particles, promoting efficient drying of milk powder in a fluidized state. The fluidized bed dry plate plate is usually made of high-quality stainless steel material, which not only ensures the long-term stable operation of the equipment but also effectively prevents pollution problems during the milk powder processing, ensuring the purity and safety of the milk powder. By optimizing the structure and distribution of the airflow distribution plate, the fluidized bed dry plate for drying milk powder can significantly improve drying efficiency, reduce energy consumption, and ensure the uniformity and quality of milk powder particles. It is one of the indispensable key equipment accessories on the milk powder production line.Our fluidized bed perforated plate is suitable for fluidized bed equipment of well-known domestic and foreign enterprises such as GEA, GLATT, ANDRITZ, etc. Welcome to consult.

MORE

Fluid Beds plate is one of the key components in fluidized bed technology. Its main function is to evenly distribute the airflow in the fluidized bed, ensuring that the materials can uniformly contact and react during the fluidization process. The design of the fluid beds plate directly affects the stability and efficiency of the fluidized bed. This plate is usually made of stainless steel material, and this one adopts a titanium plate design, which has good breathability and strength. When installing the fluid beds plate, it is necessary to ensure that it is tightly attached to the bottom of the fluidized bed to ensure even distribution of airflow. During the fluidization process, the fluid beds plate can effectively prevent the formation of channel flow and dead zones, thereby improving the fluidization quality and providing ideal conditions for the reaction. Therefore, the selection and installation of the fluid Beds plate is an important part of fluidized bed design, Our fluid beds plate is suitable for fluidized bed equipment such as GEA, GLATT, ANDRITZ, etc. If different designs or specifications are needed, they can be customized according to the drawings.

MORE

Dry granulation machine screen

Dry granulation machine screen is a key component in dry granulation equipment, primarily used for sieving and shaping granular materials. Through friction and compression, materials are forced through the screen holes, resulting in uniform granules. Typically made from stainless steel , the screen ensures durability and stability during prolonged use. The holes can be adjusted based on process requirements, making it suitable for materials with varying granule size needs. The design of the friction hole screen helps reduce dust generation, improves granule formation quality, and enhances production efficiency.We have our own mold workshop and welcome customization!

MORE

Dry granulation machines mill screen

The dry granulation machines mill screen is a key component used to separate granulated materials based on particle size, ensuring that the granules meet production standards. It works by filtering material through specific mesh openings, allowing compliant particles to proceed to the next stage, while non-compliant ones are returned for re-granulation. Made from wear-resistant materials, the screen ensures long-lasting performance and reduces clogging issues during continuous operation. The size and shape of the screen openings can be customized according to material properties and production needs, directly impacting granulation efficiency and product quality.

MORE

This cone mill screen is suitable for the Frewitt CW-150 granulator. Made of high-quality stainless steel, with a circular hole design of 1.0mm diameter, suitable for production needs that require fine particles. The 1.0mm round hole of the sieve can effectively control the particle size, ensuring that the material passes through evenly and avoids large particles from mixing into the finished product. The screen mesh is wear-resistant and corrosion-resistant, easy to disassemble and clean, ensuring production efficiency and hygiene. If you need other specifications, please feel free to call for customization.

MORE

Electrolysis cell support mesh plate

This Electrolysis cell support mesh plate is usually made of corrosion-resistant materials such as titanium, nickel, or stainless steel to resist corrosive media in the electrolytic environment. This structure can increase the surface area of the electrolytic cell, thereby enhancing the progress of the electrolytic reaction and improving the efficiency of the electrolytic cell. Secondly, it can also improve the bubble distribution and fluidity of the electrolytic cell, enhance the stability of the electrolytic cell, and is widely used in industrial fields such as chlor alkali, electroplating, and hydrogen production by electrolyzing water.

MORE

Fluid bed dryer plate is a reactor that uses gas or liquid to pass through the granular solid layer to keep the solid particles in a suspended state, and to perform a gas-solid phase reaction process or a liquid-solid phase reaction process.As a key component of the fluidized bed, the fluid bed dryer plate has strict requirements on the opening ratio, opening direction and opening height. Our company's fluid bed dryer plate has uniform mesh, smooth mesh surface, high precision of opening height and high opening density. Has been recognized by the majority of customers. We have a mold workshop, which can customize high-quality and personalized products for customers and can shorten the lead time.Our fluid bed dryer plat is suitable for fluidized bed equipment such as GEA, GLATT, ANDRITZ, etc. If different designs or specifications are needed, welcome to inquire.

MORE

This Conical sieve mill screen is suitable for the Frewitt CW-250 granulator. It adopts a 0.8mm circular hole design, with a simple structure that is easy to disassemble and clean, reducing downtime and improving production efficiency. The fine screening ability ensures the uniformity of material particles and improves the quality of the product. High quality materials and precise manufacturing processes ensure the service life and stability of the equipment. If you need other specifications and styles, please feel free to inquire.

MORE

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

图片ALT信息: Kings

违禁词: 第一,最,一流,领先,独一无二,王者,龙头,领导者,极致,

无数据提示

Sorry, the current column is being updated, please stay tuned!