KINGS

PRODUCTS

No data

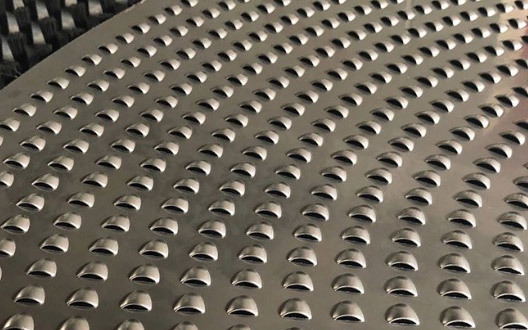

Fluidized bed plates is a special structured distribution plate widely used in fluidized bed reactors, drying equipment, and pneumatic conveying systems. Its core feature lies in the hole design - using a stepped or inclined opening structure similar to fish scales to create a swirling flow when the airflow passes through, thereby enhancing the mixing effect of gas and solid particles. Our Fluidized bed plateis suitable for fluidized bed equipment of well-known domestic and foreign enterprises such as GEA, GLATT, ANDRITZ, etc. Welcome to inquire.

MORE

Fluid bed dryer plate is a core component used in fluidized bed reactors, designed with high-precision structure and possessing uniform gas distribution capability. The core material is usually made of high temperature resistant and corrosion-resistant stainless steel material. This structure can effectively control the gas flow rate, achieve stable fluidization of solid particles, and prevent material leakage. Suitable for drying, granulation, and catalytic reaction processes in chemical, pharmaceutical, food, and other fields. Our fluid bed dryer plate is suitable for fluidized bed equipment such as GEA, GLATT, ANDRITZ, etc. Welcome to inquire.

MORE

Fluid bed dryer plate is a key component in milk powder drying equipment, with a uniformly distributed irregular pore structure on its surface and the following characteristics:

1. Uniform airflow distribution: The special arrangement can guide the hot air to form a stable fluidization, ensuring that the milk powder particles are uniformly heated.

2. Anti clogging design: reduces material residue and avoids hole blockage.

3. Efficient heat transfer: By enhancing the gas-solid contact area, drying efficiency is improved while reducing energy consumption.

This structure is widely used in the dairy industry and can significantly improve the particle integrity and drying consistency of milk powder products. Our fluidized bed mesh plate is suitable for fluidized bed equipment of well-known domestic and foreign enterprises such as GEA, GLATT, ANDRITZ, etc. Welcome to inquire .

MORE

Fluidized Bed Perforated Plates

Fluidized Bed Perforated Plate is an efficient gas distribution device widely used in fluidized bed reactors. Its design inspiration comes from the arrangement of fish scales, which achieves uniform air distribution through a unique hole layout, ensuring stable fluidization of materials in the fluidized bed. This technology solves the pain points of traditional air distribution plates being prone to clogging and high energy consumption through biomimetic design, and has now become a standard configuration for fluidized beds. Our Fluidized Bed Perforated Plate is suitable for equipment from companies such as GEA, GLATT, ANDRITZ, etc. We can also customize various specifications of Fluidized Bed Perforated Plates according to customer needs. Welcome to inquire.

MORE

Perforated Conidur plates as a key component of the fluidized bed, it has strict requirements on the opening ratio, opening direction and opening height.Our company's perforated conidur plates has uniform mesh, smooth mesh surface, high precision of opening height and high opening density. Has been recognized by the majority of customers. We have a mold workshop, which can customize high-quality and personalized products for customers and can shorten the lead time.Our Perforated Conidur plates is suitable for fluidized bed equipment such as GEA, GLATT, ANDRITZ, etc. If different specifications are needed, welcome to inquire.

MORE

Fluid bed dryer plate is a key component in fluidized bed reactors, whose core function is to ensure that the reaction medium (such as catalyst particles or solid raw materials) forms a stable fluidized state in the bed by uniformly distributing gas, thereby improving mass and heat transfer efficiency and reaction uniformity. The dryer plate is usually composed of a porous plate structure, and the hole design includes straight holes, tapered holes, or specially arranged combination holes to achieve uniform distribution of gas in the bed section. Our fluid bed dryer plate can be used for equipment from companies such as GEA, GLATT, ANDRITZ, etc. We can also customize products according to customer needs. Welcome to inquire.

MORE

This conidur fine hole screen features special triangular to semi elliptical perforations with inclined conical openings. The top and bottom are different from each other. This reduces resistance, prevents blockages, and increases production. It can ensure uniform air distribution in the fluidized bed, unobstructed openings, and enhanced crushing ability in grinding technology. This means that this wind panel can significantly improve the quality of the manufacturing process. Widely used in industries such as chemistry, food, and pharmaceuticals,If needed, please feel free to consult.

MORE

The fluidized bed dry plate for drying milk powder is a high-performance component designed specifically for the milk powder drying process. It adopts advanced porous design to ensure that the hot air flow can uniformly and stably penetrate the layer of milk powder particles, promoting efficient drying of milk powder in a fluidized state. The fluidized bed dry plate plate is usually made of high-quality stainless steel material, which not only ensures the long-term stable operation of the equipment but also effectively prevents pollution problems during the milk powder processing, ensuring the purity and safety of the milk powder. By optimizing the structure and distribution of the airflow distribution plate, the fluidized bed dry plate for drying milk powder can significantly improve drying efficiency, reduce energy consumption, and ensure the uniformity and quality of milk powder particles. It is one of the indispensable key equipment accessories on the milk powder production line.Our fluidized bed perforated plate is suitable for fluidized bed equipment of well-known domestic and foreign enterprises such as GEA, GLATT, ANDRITZ, etc. Welcome to consult.

MORE

Fluid Beds plate is one of the key components in fluidized bed technology. Its main function is to evenly distribute the airflow in the fluidized bed, ensuring that the materials can uniformly contact and react during the fluidization process. The design of the fluid beds plate directly affects the stability and efficiency of the fluidized bed. This plate is usually made of stainless steel material, and this one adopts a titanium plate design, which has good breathability and strength. When installing the fluid beds plate, it is necessary to ensure that it is tightly attached to the bottom of the fluidized bed to ensure even distribution of airflow. During the fluidization process, the fluid beds plate can effectively prevent the formation of channel flow and dead zones, thereby improving the fluidization quality and providing ideal conditions for the reaction. Therefore, the selection and installation of the fluid Beds plate is an important part of fluidized bed design, Our fluid beds plate is suitable for fluidized bed equipment such as GEA, GLATT, ANDRITZ, etc. If different designs or specifications are needed, they can be customized according to the drawings.

MORE

Fluid bed dryer plate is a reactor that uses gas or liquid to pass through the granular solid layer to keep the solid particles in a suspended state, and to perform a gas-solid phase reaction process or a liquid-solid phase reaction process.As a key component of the fluidized bed, the fluid bed dryer plate has strict requirements on the opening ratio, opening direction and opening height. Our company's fluid bed dryer plate has uniform mesh, smooth mesh surface, high precision of opening height and high opening density. Has been recognized by the majority of customers. We have a mold workshop, which can customize high-quality and personalized products for customers and can shorten the lead time.Our fluid bed dryer plat is suitable for fluidized bed equipment such as GEA, GLATT, ANDRITZ, etc. If different designs or specifications are needed, welcome to inquire.

MORE

Fluid bed dryer plates are usually designed with stainless steel perforated plates, which have high-density and uniformly distributed mesh holes. Its main design features include: uniformly distributed mesh: ensuring uniform distribution of fluidizing media and improving fluidization efficiency. High porosity: Provides sufficient permeability and reduces pressure drop.

MORE

Fluidizing conidur screen is a key component commonly used in fluidized bed reactors, used for catalytic reactions, gas adsorption, drying, and heat treatment processes. This uniquely designed mesh plate can effectively improve the flow of gas and particles, enhance the efficiency and stability of the reactor. It plays an important role in fields such as petroleum refining, chemical production, environmental protection, and new energy development. By optimizing fluid dynamics and catalyst contact, the fish scale pore shaped fluidized bed mesh helps to achieve higher yield, lower energy consumption, and more optimized product quality.

MORE

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

图片ALT信息: Kings

违禁词: 第一,最,一流,领先,独一无二,王者,龙头,领导者,极致,

无数据提示

Sorry, the current column is being updated, please stay tuned!