KINGS

NEWS

Introduction to Alkaline Electrolytic Water Hydrogen Production System

Release time:

2023-08-19 09:59

The alkaline electrolysis water hydrogen production system mainly includes the main body of the alkaline electrolysis tank and the BOP auxiliary system. This article mainly introduces the main body of alkaline electrolytic cells. Due to the wide variety of electrolytic cells and their different structures and accessories, this article only introduces the common structures of alkaline electrolytic cells for reference.

The main body of an alkaline electrolytic cell is assembled from components such as end pressure plate, sealing gasket, electrode plate, electrode, diaphragm, etc.

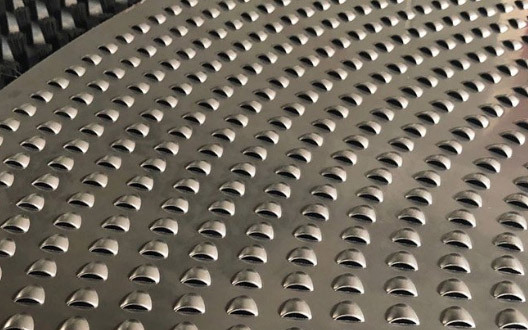

1、 Polar plate

The electrode plate is the supporting component of an alkaline electrolytic cell, which serves to support the electrode, diaphragm, and conduct electricity. The material of the domestic electrode plate is generally cast iron metal plate, nickel plate, or stainless steel metal plate. The processing method is to machine and stamp it into a papilla structure, and then weld it with the electrode frame and plating it with nickel.

2、 Polar box

There are airway holes and liquid channel holes distributed on the pole frame. The part welded to the main pole plate is called the tongue plate, the outer side of the pole frame is the sealing line area, and the rest is the overlap area of the diaphragm and sealing gasket. The entire width of the pole frame includes the width of the sealing line, the width of the flow channel area, the width of the overlap area between the diaphragm and sealing line, and the width of the tongue plate.

3、 Diaphragm

The function of the diaphragm is to prevent the mixing of hydrogen and oxygen. The diaphragm used for alkaline electrolytic cells initially used asbestos diaphragm, and currently the mainstream is polyphenylene sulfide PPS diaphragm. High performance diaphragm uses PPS coated composite membrane without base layer. In addition, key diaphragms developed by research institutes include polytetrafluoroethylene resin modified asbestos diaphragm, polyether ether ketone fiber diaphragm, polysulfone fiber diaphragm, etc.

4、 Insulation sealing materials and clamping devices

The insulation material that supports the entire tank body is usually made of porcelain insulation seats or electrical insulation plates, while the insulation material that supports the electrode plate and frame is made of small porcelain seats or bakelite insulation sleeves. The insulation and sealing material between the electrodes (frames) is now a "cloth pad in one" structure. After being clamped, the electrolytic chamber becomes a groove, and the clamping device is composed of two end plates, large screws, nuts, spring discs, and insulation sleeves. Due to thermal expansion and contraction, the size of the tank body changes from time to time, which relies on the force of the spring disc to maintain the tank body in a compressed state.

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

无数据提示

Sorry, the current column is being updated, please stay tuned!