KINGS

PRODUCTS

No data

In industrial production such as chemical, food, and pharmaceutical industries, conical screen mesh is an essential key equipment. It can filter liquids, gases, and solid particles, not only improving product quality, but also reducing equipment blockage, lowering maintenance costs, and improving production efficiency. In addition, conical mesh can filter various specific sizes of small particles and particles in the air, and even filter solid, liquid, and gas fluids with certain density and special chemical properties. The structure of the conical sieve is unique and has multiple advantages. Its design makes the screening process more efficient, while also being easy to clean and maintain. In addition, the conical sieve also has high durability and stability, and can operate stably for a long time in harsh working environments. Our conical mill screen can be adapted to equipment from companies such as Frewitt, Quadro Comil, Glatt, Bohle, and so on. Please feel free to call us for customization.

MORE

The cone mill screen is a core screening component designed with a conical structure, which achieves efficient classification and filtration of materials through a step-by-step screening mechanism. Its screen surface is usually made of stainless steel (such as 304/316L), which has both wear-resistant and corrosion-resistant properties, and is suitable for harsh production environments such as pharmaceuticals, food, and chemicals. The sieve holes are designed with wedge-shaped mesh or file shaped holes (trapezoidal cross-section), which can reduce clogging and improve screening accuracy. This sieve drives material movement through rotation or vibration, combined with self-cleaning function, to achieve particle shaping, solid-liquid separation, and impurity removal. Mainly used in the fields of sterile raw material granulation, freeze-dried powder loosening, ore grading, and grain impurity separation, it supports customization of different pore sizes to meet different particle size control requirements. Welcome to consult.

MORE

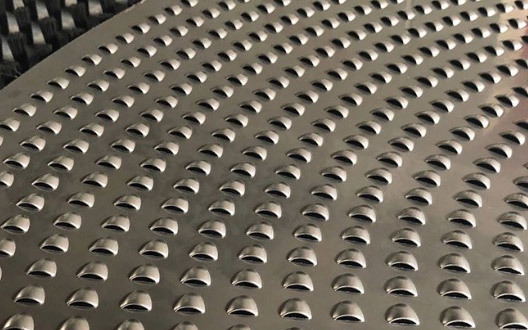

Cone mill screen-conidur hole screen

The conidur hole screen is a core component designed for efficient cutting. It adopts a conical structure and filing tooth shaped hole pattern to achieve fine granulation of hard or large particle materials through extrusion and shearing. Its stainless steel material (such as 304/316L) has both wear resistance and corrosion resistance, which can meet the demanding production environment requirements of sterile raw materials such as pharmaceuticals.

Compared to flat screens, conidur hole screen can reduce particle breakage, increase screening efficiency by more than three times, and effectively prevent screen hole blockage. Support customization of multiple aperture sizes as needed. This sieve is compatible with mainstream models such as Frewitt and Quadro, and is widely used in dry and wet granulation processes in the pharmaceutical, chemical, and food industries. Welcome to consult.

MORE

The cone mill screen is the core filtering component in the granulator, designed with a conical structure to achieve material classification and screening through vibration or rotation. Its stainless steel material has wear-resistant and corrosion-resistant properties, and the sieve aperture can be customized to meet different particle size requirements. This screen uses centrifugal force to separate qualified particles and residues, and with a step-by-step screening mechanism, it can efficiently process materials such as powders and particles. Mainly used in the pharmaceutical (such as sterile raw material granules), chemical, and food industries.The specifications of the screen of the square hole granulator include 3 * 3mm, 4 * 4mm, 5 * 5mm, and so on,Welcome to inquire.

MORE

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

图片ALT信息: Kings

违禁词: 第一,最,一流,领先,独一无二,王者,龙头,领导者,极致,

无数据提示

Sorry, the current column is being updated, please stay tuned!