KINGS

PRODUCTS

No data

The granulator cone screen is an important equipment accessory used in the grain processing industry, mainly used to screen impurities and particles of different particle sizes in raw materials. The screening screen of the whole granulator has the characteristics of high temperature resistance, corrosion resistance, and wear resistance. It can work stably for a long time and has high screening efficiency and accuracy, which can effectively improve product quality and production efficiency. It is widely used in industries such as grain processing, food processing, and chemical industry, playing an important role in processes such as grain cleaning and particle sorting.

MORE

This granulator screen is easy to clean and disassemble. According to different particle size requirements, the mesh size of the screen in the equipment granulation system can be changed, and the most suitable screen can be customized according to drawings or samples.

MORE

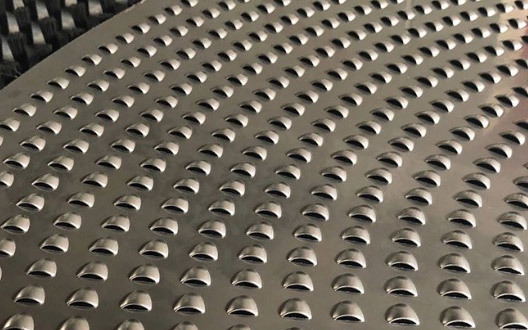

Triangle Raised-hole screens is widely used in food machinery, pharmaceutical equipment, chemical machinery, the opening height and angle of fish scale hole can be adjusted according to the demand. For example, a hole of 0.5mm is stamped on a plate with a thickness of 1.0mm; the opening of the hole has a certain height, which can control the direction of the airflow. The holes are all deburred and the surface is smooth. Electropolished stainless steel can significantly reduce the chance of fine particles on the hole and reduce the effect of flow rate. perfocon is a branded product specially designed by RMIG.

MORE

Dry granulator screen is one of the crucial components in the dry granulation machine. It undertakes the task of screening and separating raw materials, ensuring uniformity and quality in the granulation process. Customization can be made according to different raw material characteristics and granulation requirements. When using a dry granulator screen, the operation is simple. Simply put the raw materials into the feeding port, and the machine can screen out particles that meet the requirements through rotational motion and vibration, and output them to downstream equipment or collection containers. Moreover, dry granulator screen is easy to clean and maintain, which is beneficial for maintaining the hygiene and long-term stable operation of production equipment.

MORE

The fluidized bed is a reactor that uses gas or liquid to pass through the granular solid layer to keep the solid particles in a suspended state, and to perform a gas-solid phase reaction process or a liquid-solid phase reaction process.As a key component of the fluidized bed, the sieve plate of the fluidized bed has strict requirements on the opening ratio, opening direction and opening height. Our company's fluidized bed sieve plate has uniform mesh, smooth mesh surface, high precision of opening height and high opening density. Has been recognized by the majority of customers. The company has a precision mold workshop, which can customize high-quality and personalized products for customers. And can shorten the lead time.

MORE

Due to the protrusion of the coni-perf holes, the distance between the hammer and sieve is correspondingly shortened, which not only reduces the thickness of the material flow layer, reduces the obstruction of the material passing through the sieve plate, but also increases the resistance of the material flow, slows down the flow rate, and increases the opportunity for the material to pass through the sieve holes. Of particular importance, it can change the movement pattern of materials, from laminar movement close to the inside of the sieve plate to pulsating movement, greatly increasing the opportunity for materials to pass through the sieve holes. The fish scale hole sieve plate has received praise from many users during use.

MORE

Fluidized bed perforated plate

The design and arrangement of Fluidized bed perforated plate used for drying milk powder are crucial for the drying effect of milk powder. They usually require the design of appropriate ventilation holes and spacing to ensure that hot air can evenly and effectively expel water vapor, thereby ensuring that milk powder can dry quickly and uniformly. At the same time, the structural design of the airflow distribution plate should also consider avoiding clumping or adhesion of milk powder during the drying process to ensure the quality and appearance of the final product. Our fluidized bed perforated plate is suitable for fluidized bed equipment of well-known domestic and foreign enterprises such as GEA, GLATT, ANDRITZ, etc. Welcome to consult.

MORE

Metal perforated plates is an industrial product that forms regular holes on metal or non-metal sheets through precision stamping technology. The core process is to use CNC punching machines or molds to perform high-speed punching and cutting of sheet metal, forming various hole types such as circular, square, diamond, etc., and can design different hole spacing, arrangement (such as straight or staggered), and opening rate according to requirements. Common materials include stainless steel, galvanized steel, aluminum alloy, and engineering plastics. The surface can be treated with spraying, electroplating, and other methods to enhance corrosion resistance. As a multifunctional profile, punched plates have the characteristics of structural support and functional penetration. They are used in the field of building curtain wall decoration and ventilation partitions, and the aperture design can balance light transmittance and privacy requirements; When used as a screening filter in industrial scenarios, precise hole spacing can accurately control material particle size; Its honeycomb structure can effectively disperse stress and is commonly used in mechanical equipment protective covers and automotive mufflers. In modern design, designers use gradient hole patterns and artistic pattern punching to create interactive facade effects of light and shadow, endowing products with aesthetic value. Our company can customize various punching plates according to needs. Welcome to inquire us.

MORE

Electrode support mesh plate for hydrogen electrolysis cell

The Electrode support mesh plate for hydrogen electrolysis cell is a key component in the hydrogen production device by electrolyzing water, mainly used to provide mechanical and electrical conductivity for the electrode, and must have good corrosion resistance. Common materials include stainless steel, nickel alloy, and titanium. This double-sided bridge type stretching structure of the electrode plate support mesh plate has the advantages of low resistance and high hydrogen production efficiency compared to the traditional nipple type stretching structure of the electrode plate support mesh plate, and is widely used in industrial hydrogen production, fuel cell hydrogen production and other fields.

MORE

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

图片ALT信息: Kings

违禁词: 第一,最,一流,领先,独一无二,王者,龙头,领导者,极致,

无数据提示

Sorry, the current column is being updated, please stay tuned!