KINGS

NEWS

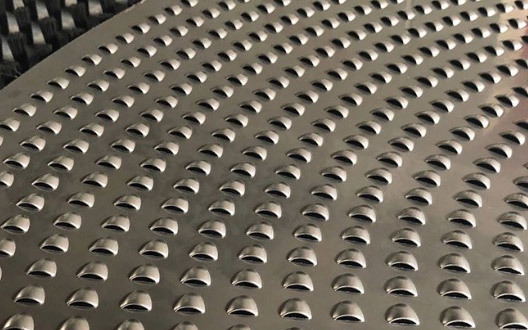

The role of Fluidized bed sieve plate

Release time:

2023-11-27 09:57

The main functions of the fluidized bed distribution plate are:

1. Support solid particle materials.

2. Ensure uniform distribution of gas when passing through the distribution plate.

3. Disperse the airflow and generate smaller bubbles above the distribution plate.

When fluidized bed drying equipment is drying materials, if the airflow distribution is uneven, it will cause the airflow velocity in certain parts of the bed layer of the fluidized bed drying equipment to be higher, and more bubbles will result in a lower overall density of the bed layer; In contrast, in other areas, the bed density is higher, resulting in a phenomenon known as circulation.

The distribution plate is equivalent to many parallel pipelines, and in order to achieve uniform airflow distribution, it is necessary to make the pressure loss on both sides of each hole equal. But in actual production, it will be influenced by many factors. The reason is 1. The dynamic pressure head of the inlet fluid is different at various points below the distribution plate. The fluid velocity directly facing the inlet pipe is higher, resulting in a larger dynamic pressure head.

Therefore, the pore velocity in the middle part of the distribution plate is higher.

2. The violent fluctuations in the bed layer result in uneven height and porosity of the particle columns at various points on the distribution board, leading to different static pressure heads acting on each point on the distribution board. Therefore, it is necessary to ensure that the pressure loss of gas passing through the distribution plate holes exceeds the deviation caused by the above factors, so that the latter can be ignored and the airflow distribution is uniform. According to experiments, the pressure loss of the distribution plate is generally 10% -40% of the bed pressure loss of the fluidized bed drying equipment.

The resistance of gas passing through the pore depends on the ratio of the cross-sectional area of the pore to the container and the gas flow rate inside the pore. Experiments have shown that the larger the opening rate of general fluidized bed drying equipment, the poorer the vulcanization quality; Reducing the porosity can improve the vulcanization quality. But if the opening rate is too small, it will cause excessive resistance and increase power consumption. The opening rate of the distribution plate in general fluidized bed drying equipment is set at 3% -8%, and its lower limit is commonly used for low vulcanization speed, that is, drying materials with fine particles and low density. The aperture of the fluidized bed distribution plate produced by our company is usually 1.0-2.5mm, with a small aperture of 0.15mm and a large aperture of 5mm.

RELATED NEWS

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

无数据提示

Sorry, the current column is being updated, please stay tuned!