KINGS

NEWS

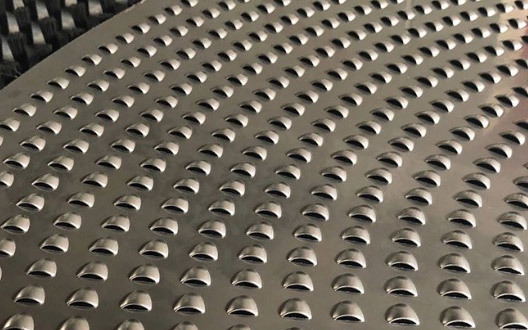

Introduction to Fluidized bed dryer plate for drying milk powder

Release time:

2025-03-01 11:18

As the core component of milk powder drying equipment, the design of fluidized bed dryer plate directly affects drying efficiency, product uniformity, and energy consumption control. The following are the key features and functions:

1. The dryer plate disperses hot air to the bottom of the bed through a porous structure, ensuring sufficient fluidization of milk powder particles and avoiding local accumulation. The pressure drop is usually set to more than 10% of the total pressure drop in the bed, ensuring both uniform airflow and energy consumption control.

2. Stainless steel material is usually used, with a smooth surface to reduce material adhesion and meet food grade hygiene requirements. In some designs, the distribution board and support structure form an air chamber, and the airflow distribution is further optimized through side or uniform air gaps.

3. Set up a blending zone below the feed inlet to enhance local fluidization speed by adjusting the air volume, allowing wet milk powder particles to quickly disperse and dry, preventing agglomeration. Combined with vibration devices (such as vibration motors), the dryer plate drives particles to roll, extending heat exchangeTime, while reducing damage to thermosensitive components.

4. Some equipment adopts a multi-layer dryer plate design, with each layer controlled by an overflow weir to ensure that the moisture gradient decreases step by step, in order to meet the drying needs of milk powder with different moisture contents.

5. Built in heat exchange coils may be installed above the dryer plate to enhance heat transfer through fluidized particle flushing, but regular maintenance is required to prevent wear and leakage.

Our company can customize various styles of fluidized bed distribution boards. Welcome to inquire .

RELATED NEWS

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

无数据提示

Sorry, the current column is being updated, please stay tuned!