KINGS

NEWS

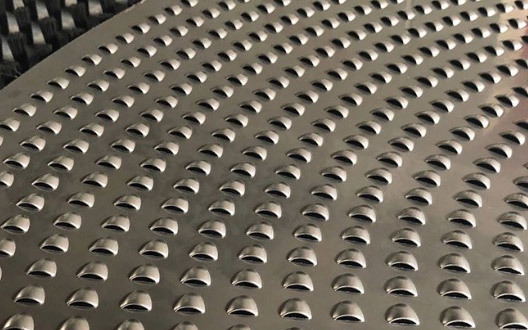

conical mill screen

Release time:

2025-09-09 15:00

In industries such as food processing, pharmaceutical manufacturing, and chemical production that rely on powder processing, the screening components of grinding equipment always play a key role. A screen with stable performance and strong durability can not only ensure the particle size uniformity of powder products, but also reduce equipment maintenance costs and improve overall production efficiency. The cone mill screen launched by Yangzhou Kings Shield Mold Technology Co., Ltd. has been comprehensively optimized in terms of material, structure, and ease of use based on the actual needs of the industry.

From the perspective of material selection, the cone mill screen is made of durable stainless steel, which has excellent wear resistance and corrosion resistance. In the process of long-term exposure to various materials (such as food raw materials, pharmaceutical intermediates, chemical powders, etc.), it can resist the wear and tear caused by material friction, extend its own service life, and cope with the influence of some corrosive materials, avoiding product contamination caused by screen rust and providing a basic guarantee for product quality in subsequent production processes.

In terms of structural design, the sieve adopts a unique conical structure, which can play an important role in the grinding process. After the material enters the grinding equipment, the conical sieve can guide the material to gradually complete the process of reducing particle size, avoiding the problem of uneven grinding caused by material accumulation in a certain area, and ultimately ensuring that the output powder is uniform and fine, meeting the strict requirements of different industries for powder particle size. At the same time, the aperture of the sieve can be flexibly selected according to production needs. Whether it is the pharmaceutical industry that requires fine powder or the food processing industry that has specific standards for particle size, the appropriate aperture of the sieve can be matched to accurately control product particle size and improve product consistency.

In practical use scenarios, the advantages of this screen mesh are further highlighted. Its design is simple, the disassembly and cleaning process is convenient, and the staff can replace and maintain the screen mesh without complex operations. This feature not only reduces equipment downtime for maintenance and lowers labor costs, but also effectively avoids material cross contamination caused by incomplete mesh cleaning, especially suitable for the food and pharmaceutical industries that have high requirements for production environments. In addition, the durable materials and scientific structural design indirectly extend the service life of the entire grinding equipment, helping enterprises reduce the investment in equipment updates and iterations, and ensuring the continuity and stability of production.

RELATED NEWS

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

无数据提示

Sorry, the current column is being updated, please stay tuned!