KINGS

NEWS

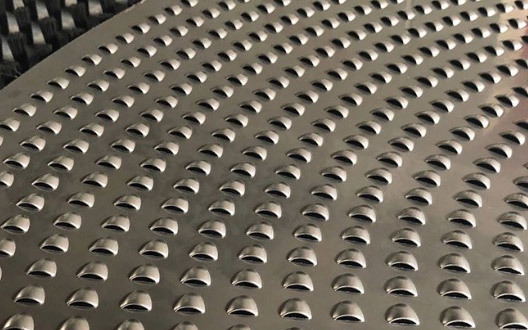

The benefits of combining dryer conveyor mesh plate and butterfly plate

Release time:

2025-10-07 16:30

The design of combining the conveyor mesh plate and butterfly plate in the dryer mainly focuses on material conveying, hot air distribution, and efficiency optimization in the drying process, with the following core advantages:

1. Improve drying uniformity

Function of the mesh plate: As a basic conveying carrier, it allows hot air to penetrate the material layer and avoid heat accumulation at the bottom.

Butterfly plate assistance: Butterfly boards can guide the flow of hot air, reduce dead corners, and ensure even distribution of heat between materials.

2. Enhance material adaptability

Stability of mesh plate: Suitable for carrying fragile or loose materials (such as particles, feed), preventing deformation or accumulation.

Butterfly plate adjustment: By adjusting the angle or spacing of the butterfly plate, the material flow rate and paving thickness can be controlled to meet the drying needs of different humidity and viscosity.

3. Energy saving and efficiency optimization

Hot air circulation: The breathability of the mesh plate combined with the air duct design of the butterfly board can reduce hot air waste, improve heat utilization efficiency, and reduce energy consumption.

Anti blocking design: The butterfly plate can prevent material adhesion or blockage of the mesh, reducing downtime for cleaning.

4. Extend the lifespan of equipment

Reduce wear: The synergistic effect of mesh and butterfly plates can reduce the impact of materials on the conveyor belt, while avoiding metal fatigue caused by local overheating.

Maintainability: Modular design facilitates quick replacement of damaged mesh panels or adjustment of butterfly panel angles.

RELATED NEWS

SAF Coolest v1.3.1.2 设置面板 YXHSX-AUQD-ISSVE-XAW

无数据提示

Sorry, the current column is being updated, please stay tuned!